With the continuous development of industrial economy, the world environment is becoming worse and worse. Especially with the development of the industrialization of developing countries, the absolute amount of pollutants discharged into the atmosphere is increasing rapidly. Human beings are increasingly being tired of the consequences of their own, and even fear. Sulfur dioxide emissions from coal-fired power plants is one of the main factors that cause air pollution, which can not only cause acid rain harm to human beings, but according to the latest world environmental experts assert, or damage to the ozone layer of an important factor. Therefore, the governance of sulfur dioxide is imminent.

China's flue gas desulfurization situation: at present, the domestic flue gas desulfurization more use of the limestone - gypsum method. With the large-scale application of the process, the operation cost is high, the by-product desulphurization gypsum disposal is difficult, the increase of the carbon dioxide emissions and other issues become increasingly prominent, resulting in a more obvious environmental and resource issues. In view of the above situation, in recent years, the State encourages the development and application of new desulfurization technology, in particular, to support the promotion of resource recycling based green environmentally friendly desulfurization technology.

Resource recycling wet ammonia flue gas desulfurization technology is a kind of green desulfurization process, which can realize the circular economy. It is suitable for China's national conditions. It is worth to be popularized in China. It is a kind of technology which is suitable for China.

Resource recycling type wet ammonia flue gas desulfurization technology with ammonia (ammonia, ammonia, etc.) as absorbent, SO2 removal in flue gas and recovering process for FGD by-product ammonium sulfate.

Reaction principle is divided into the following two steps:

(1) the absorption process of NH3 and SO2 in aqueous solution: SO2 + H2O + xNH3 + xH2 = (NH4) xSO3; SO2 removal in the waste gas by ammonia, and the intermediate product of ammonium sulfite was obtained.

(2) xH2-xSO3+1/2O2 (NH4) + (NH4) NH3= () 2SO4 (2-x) is used for direct forced oxidation by air;

This process is will absorb the intermediate product of the reaction of instability of ammonium bisulfite oxidation into stable ammonium sulfate, namely agricultural ammonium sulfate fertilizer.

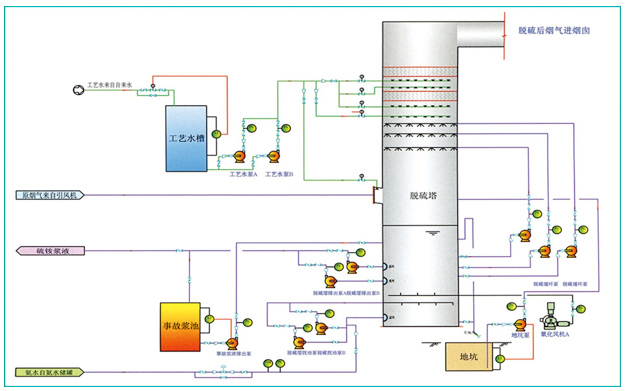

After entering the desulfurization device by the boiler air guide fan (or the gas desulfurization booster fan), the ammonia absorption liquid cooling and reaction to produce sodium hydrogen sulfate. Net flue gas desulfurization through removing fog and mist amount less than 75mg / Nm3, desulfurization efficiency greater than 95%, and ammonium hydrogen sulfite solution is drum into the air oxidation of the ammonium sulfate solution, ammonium sulfate solution in the washing and cooling process itself (crystallization) evacuation concentrate into ammonium sulfate device.

Solid slurry is fed to a cyclone, a centrifuge for solid-liquid separation, forming a wet ammonium sulfate, the mother liquor back to the desulfurization system; wet ammonium sulfate by drying backward packing machine can be obtained commercial ammonium sulfate.

Keywords in-situ conditions include: gas phase precipitation, ammonium sulfate crystallization, solid powder, crystal, PH=2.5~4 field, temperature of 60 degrees, pressure difference 5~6bar, operation density 1.2~1.5g/cm3, ammonium sulfate slurry, solid ammonium sulfite, ammonium sulfate node crystal and acidic environment, liquid. Ammonia desulfurization is easy to be produced in the gas phase precipitation, namely in the gas phase formation solid ammonium hydrogen sulfite and ammonium sulfate under certain temperature to the crystalline state, solid powder and crystallization of ammonium sulfate for equipment and valves damage is very serious, especially the acidic environment of the desulfurization system, makes the whole operation both wear and corrosion, the valve device is very high. The scene often damaged, switch valve leak, not problems. Whether it is cold or heat, once the valve problem, on-site technical professionals work are to be replaced, maintenance, on-site engineering college of this miserable.

In view of the above the harsh conditions, Jintai Merrill Lynch technology professionals work actively participate in, and users together communicate to resolve, the natural advantages of zirconia ceramics, with with years of experience and practice, design and development of super wear-resisting, ultra resistant to corrosion, sealing a high degree of KOWOV ceramic ball valve, effectively solve the above problems.

Jintai Merrill Lynch KOWOV ceramic ball valve with high mechanical properties of zirconia ceramic and unique structure, using ceramic natural advantage (super wear resistance and corrosion resistance), a comprehensive solution to the valve problem of ammonia desulfurization method.

All parts of the contact with the media are structural ceramic materials, their chemical stability and high hardness (HRC90), second only to diamond. Therefore, KOWOV ceramic ball valve has a very high wear resistance, corrosion resistance, erosion resistance, and good heat insulation, thermal expansion is small.

Ball adopts the advanced grinding equipment and manufacturing process, a round ball precision high, can achieve 1um) and surface quality good (surface roughness of 0.2um), and the ceramic valve seat on the research, the use of Zr02 ceramics self lubrication, made light of the torque and good sealing performance, can achieve zero leakage).

The overall structure of the floating ball structure, by the fluid pressure or preload to seal; using ceramic inorganic non metal materials, can easily avoid scuffing the ball core locking sealing.

Over the past decade, KOWOV ceramic ball valve has been successfully applied to all kinds of desulfurization system (limestone desulfurization slurry, magnesium desulfurization method, seawater desulphurization, etc.); slurry system (limestone desulfurization soda lime milk system); silica fume, sand transport (polycrystalline silicon, silicon, precision casting); slag water system (water for removing slag, sinter dust, coal cinder renewable resources), outstanding performance

In our valve successfully applied to the scene 30 months, we have the opportunity to visit the use of the valve is still good, there is no quality problems, for this purpose we have been highly recognized by customers, the quality of the valve is strongly praised, greatly reducing their maintenance and maintenance costs, said it should be vigorously promoted.